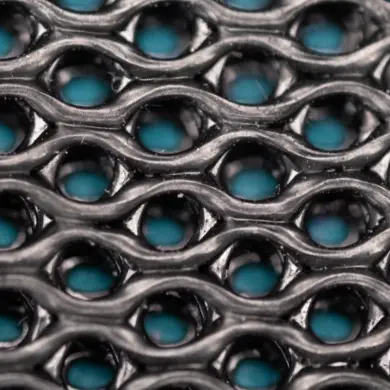

NEXT GENERATION POLYURETHANE

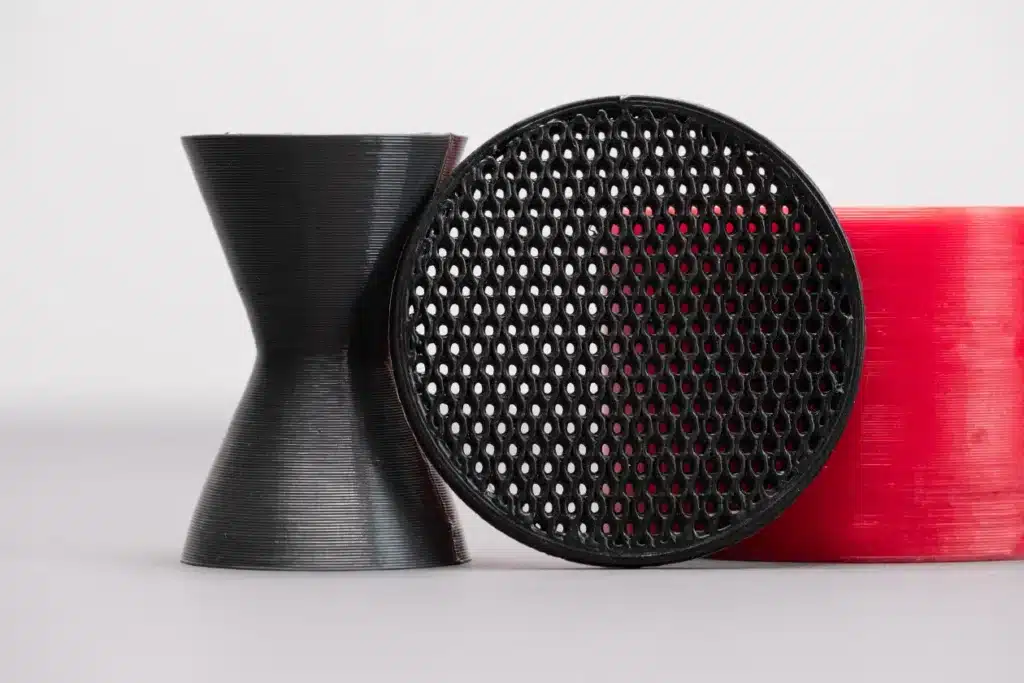

- Print unique shapes without the constraints imposed by the moulding process

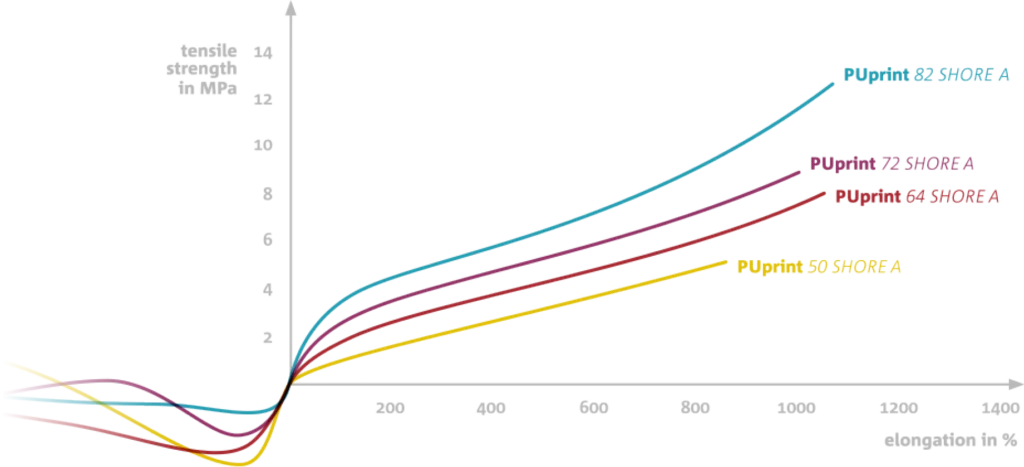

- As tough as vacuum casting PUs

- From soft to semi rigid with four different hardness levels available

- High mechanical and thermal resistance

space

space

- The SYNTHЭD+ PUprint line-up has the same very high mechanical and thermal properties as SYNTHENE’s elastomer range

- PUprint provides a sturdy alternative to the existing TPU filament materials

space

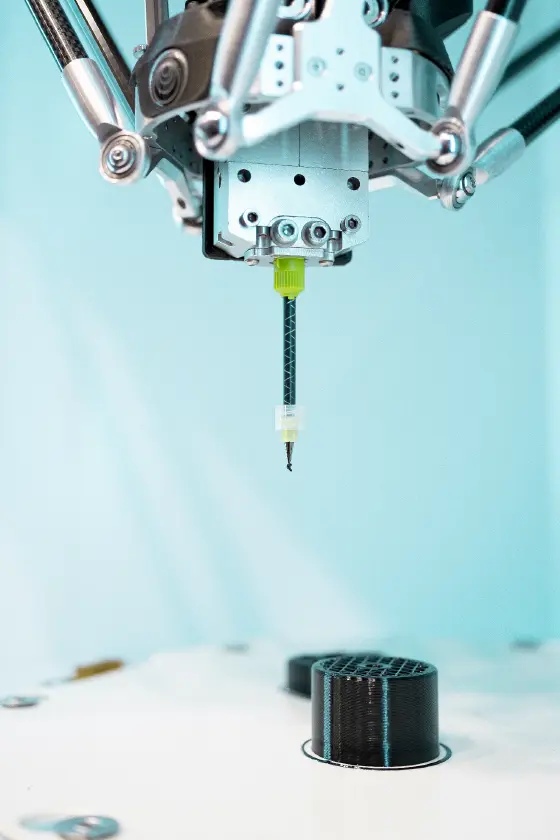

- Clients have already ordered the first 3D printers to print this cutting edge material with high demand from sectors like defence, aviation, automotive and other industries with high demands on quality

space

- PUprint is the first system to be launched in the SYNTHЭD+ range which will be dedicated to additive manufacturing

- SYNTHENE’s mindset is to bring high performance to the 3D printing industry for fully functional parts that are as resistant as conventionally produced parts

Documents

Management Summary RUBBER PUprint

Quick handout summarising the technical characteristics of SYNTHЭD+ PUprint, SYNTHENE’s first two-component polyurethane that can be 3D-printed.

fully functional 3D-printed parts

PRINT ANY SHAPE

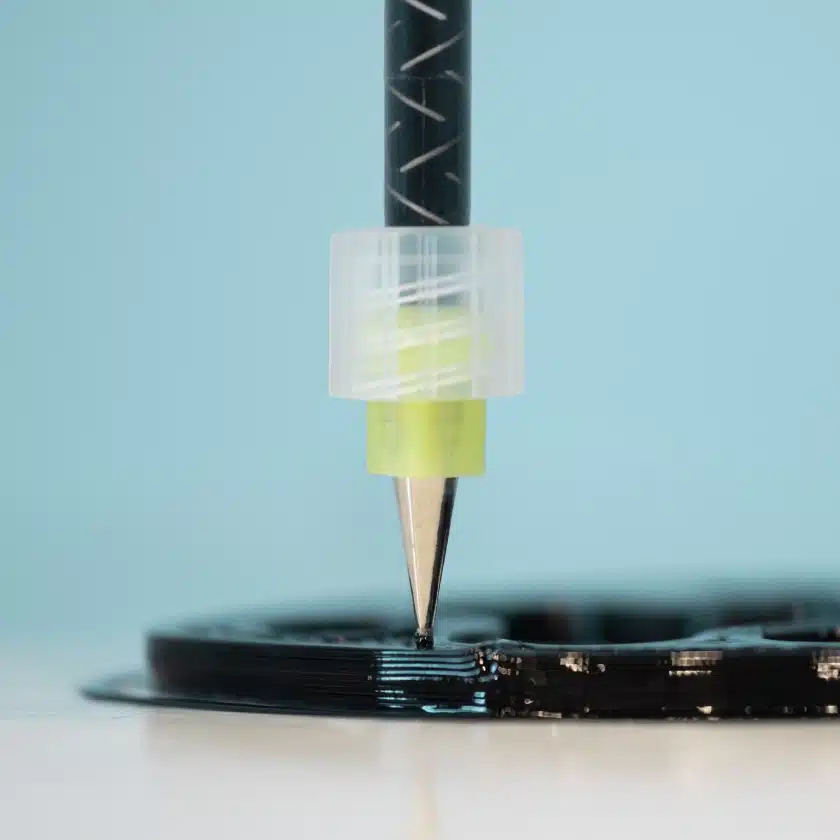

Any imaginable shaped object is 3D-printable with PUprint thanks to a specific formulation to produce high- precision parts.

PRINT LIGHTER PIECES

By reducing the amount of filling the parts can become lighter and more flexible.

AS TOUGH AS VACUUM CASTING PU

The mechanical properties of SYNTHЭD+ PUprint are as good as of conventional PUs for vacuum casting.

HIGH THERMAL RESISTANCE

SYNTHЭD+ PUprint stands out with its high thermal resistance comparable to conventional industrial parts.