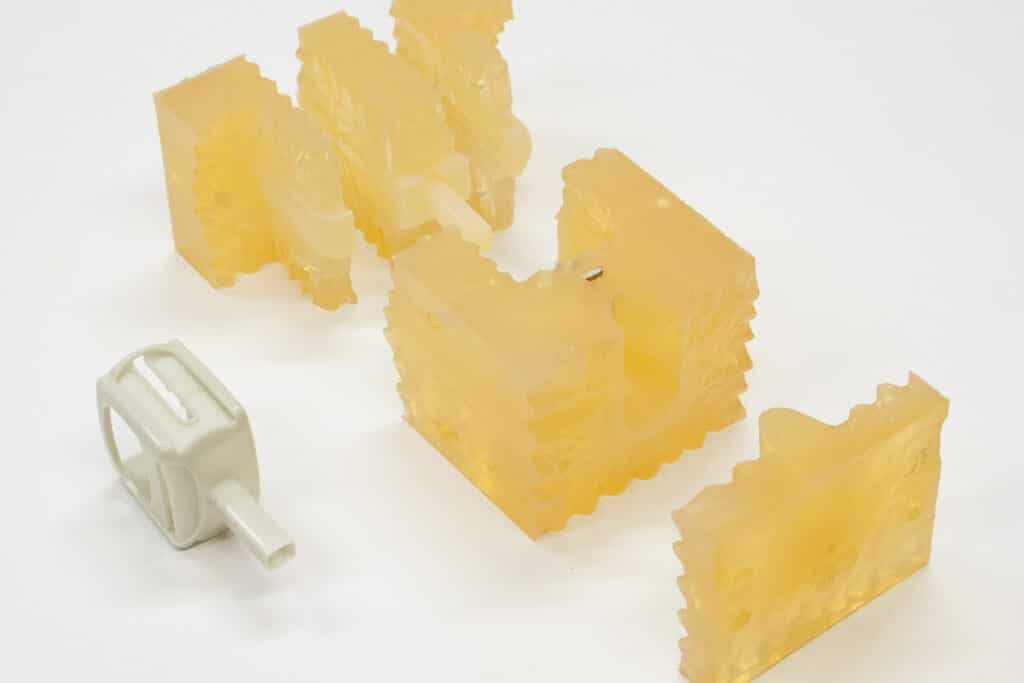

Elastomers for all applications strength for prototyping rubber-like parts.

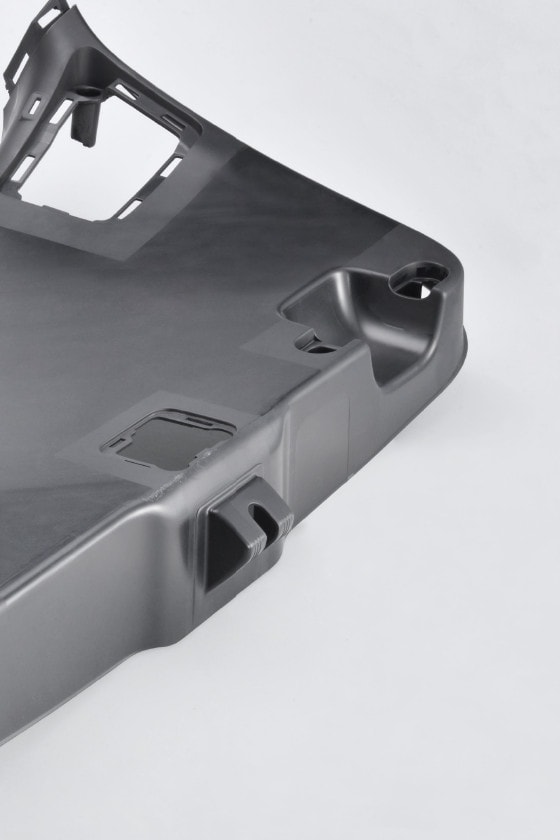

- The versatile HPE with high mechanical and chemical resistance, suitable for small to massive parts

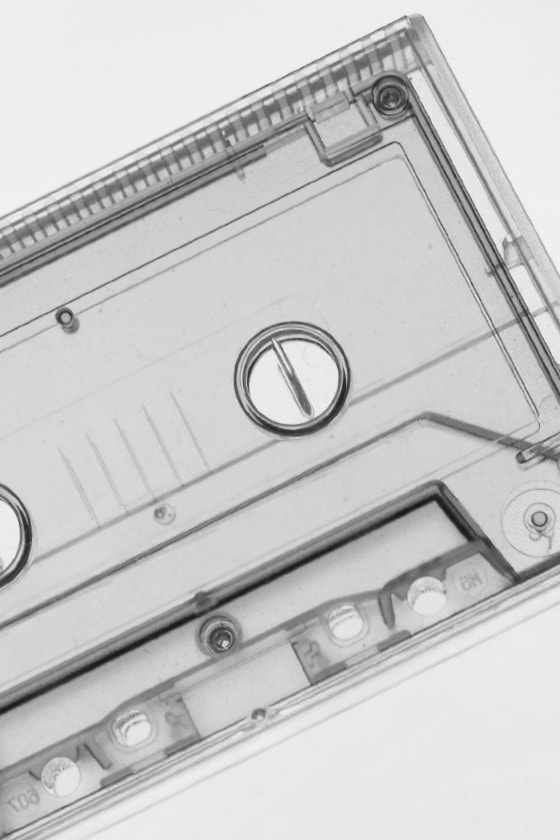

- The quick FASTELAST, colourable material with strong properties within one to two hours

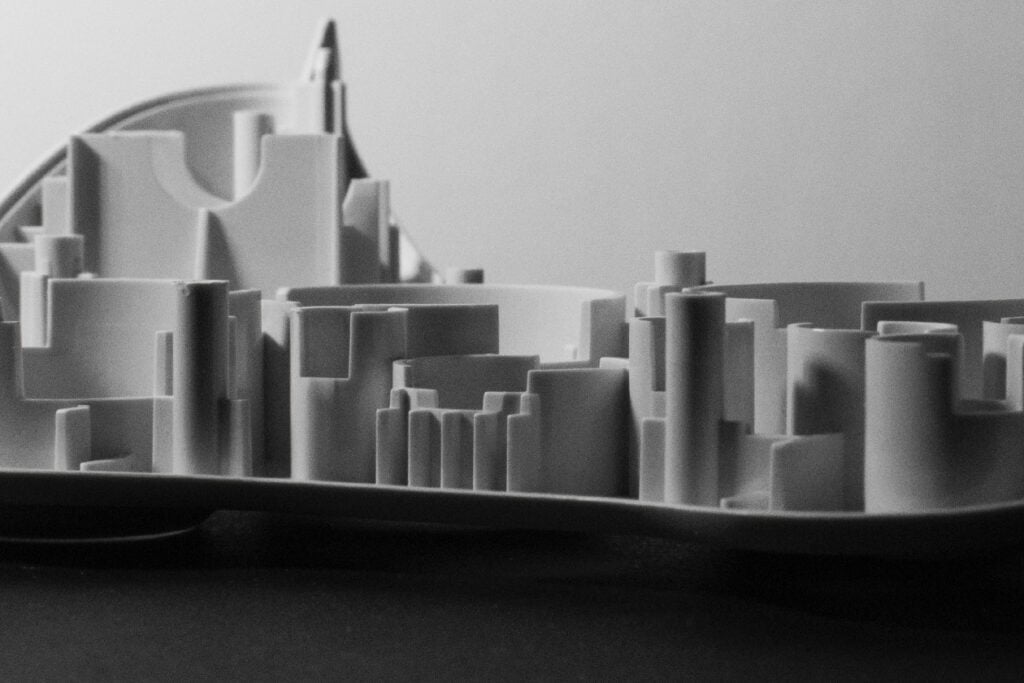

- The semi-flexible HPR65 with high impact resistance and flexibility

SYNTHENE makes a point of offering a high level of performance though a range of upscale PU rubbers with a high level of tear resistance, even on notched parts.