PROTOTYPING RESINS & ELASTOMERS for strong and functional parts.

- Vacuum casting resins to simulate many types of thermoplastic materials

- From the most basic to the highest level of requirement with specific standards as UV stability, UL94 V0 or food compatibility

- Elastomers with high mechanical and chemical resistance

- Optimised production with fast demoulding materials and non-aggressive formulas for long-lasting moulds

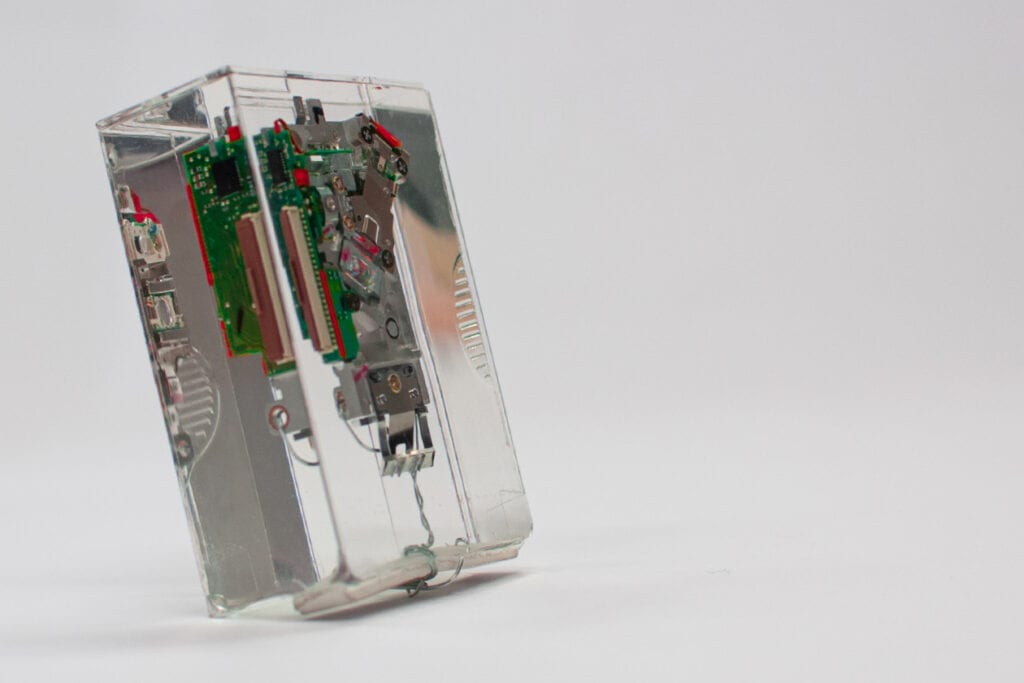

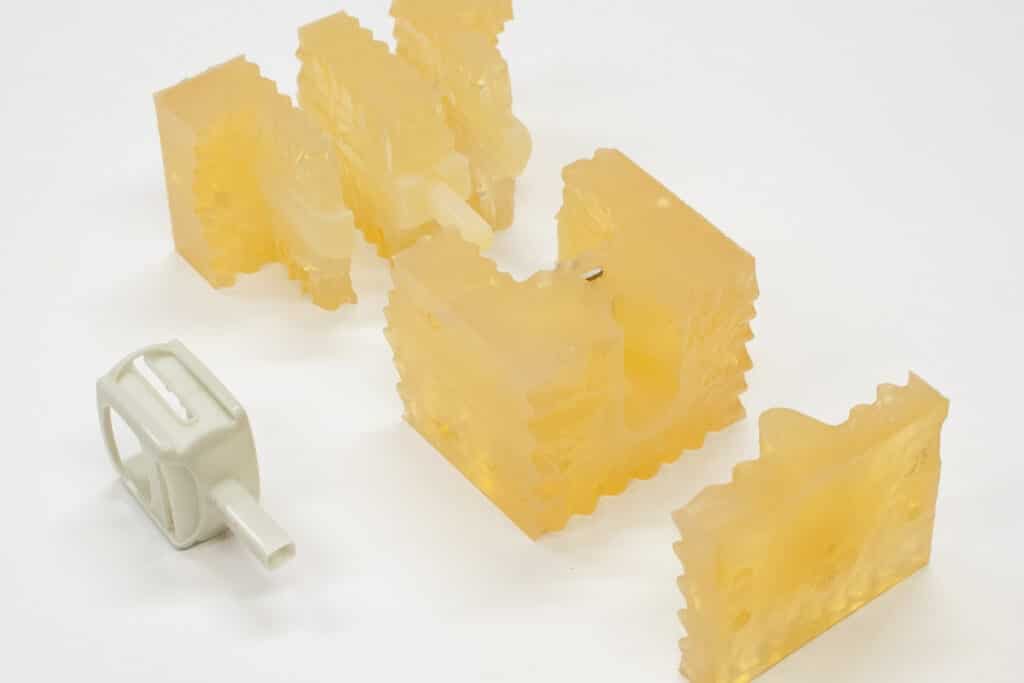

This process consists in mixing and casting liquid PU into a polyaddition silicone mould, inside a vacuum casting machine. The mould is then placed in an oven for the curing step before demoulding. This results in a strong and functional countertype of thermoplastic (e.g. HDPE, ABS, PC…) that can be used as a prototype or small series.