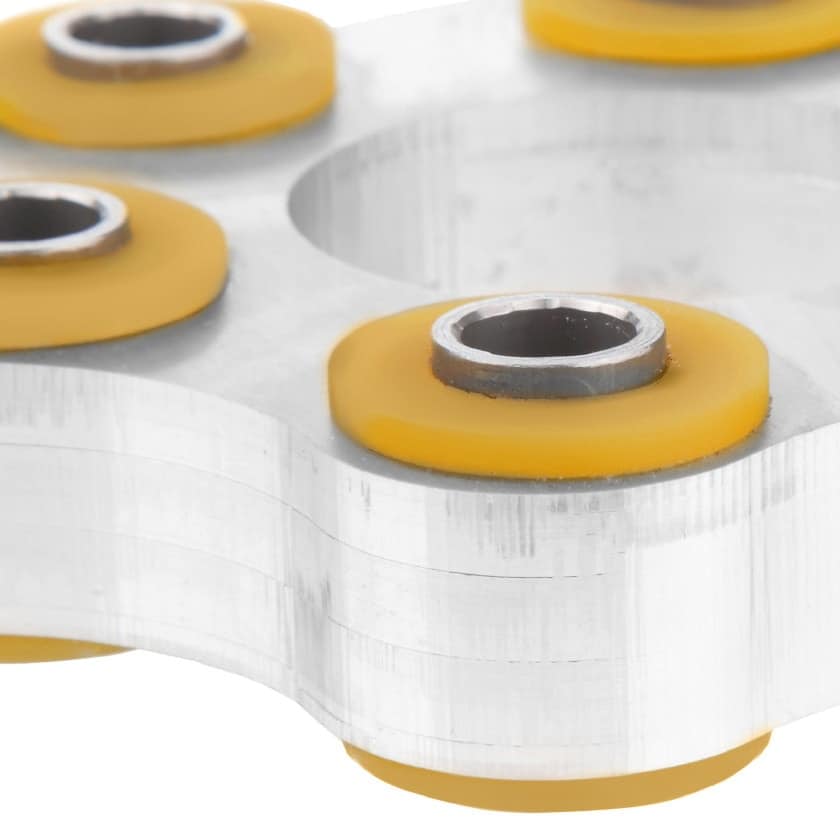

HPE INDUSTRIAL ELASTOMERS from 40 Shore A to 55 Shore D

- A comprehensive system of rubber material for strongly stressed parts, even notched

- High chemical resistance for an efficient use even for submarine applications

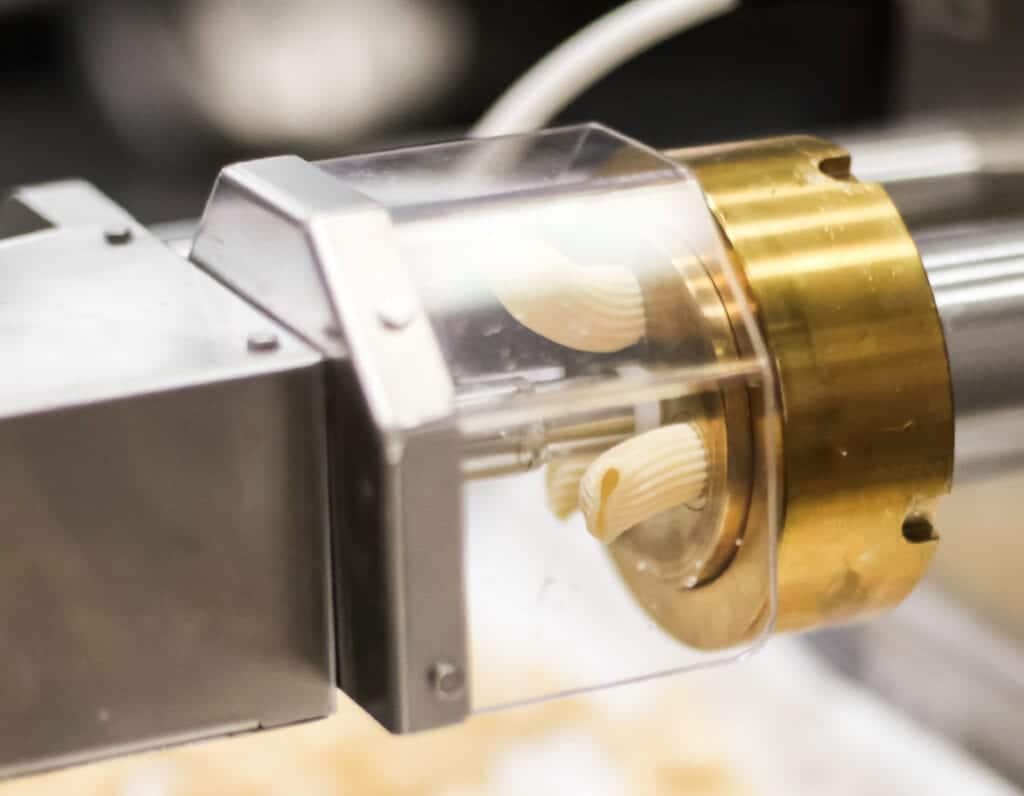

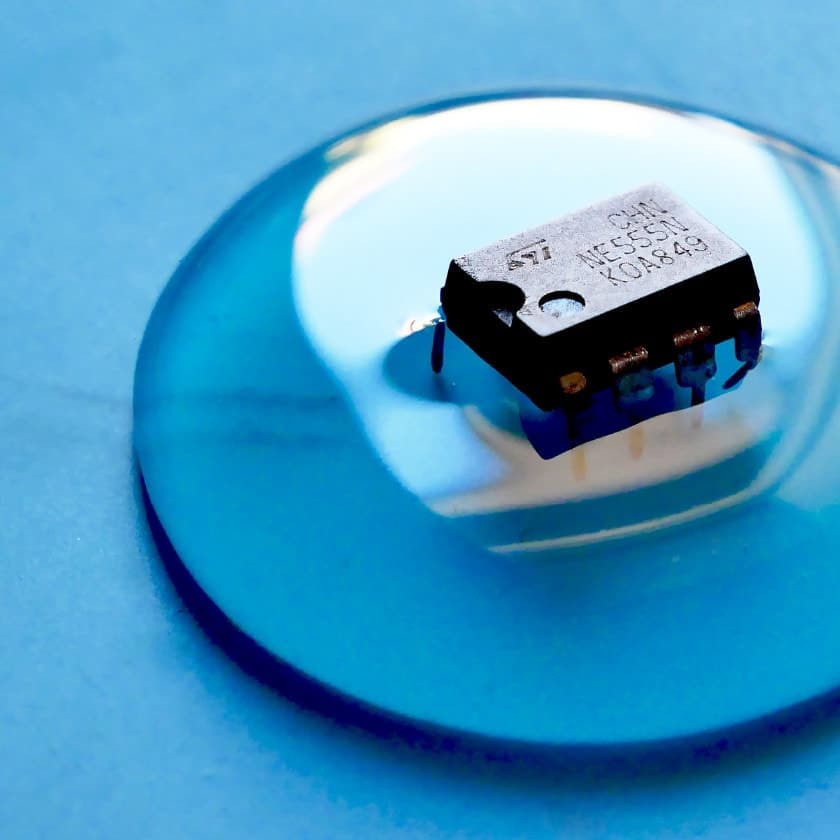

- Open processing possibilities: hand-casting, vacuum casting machine and two-component mixing machine

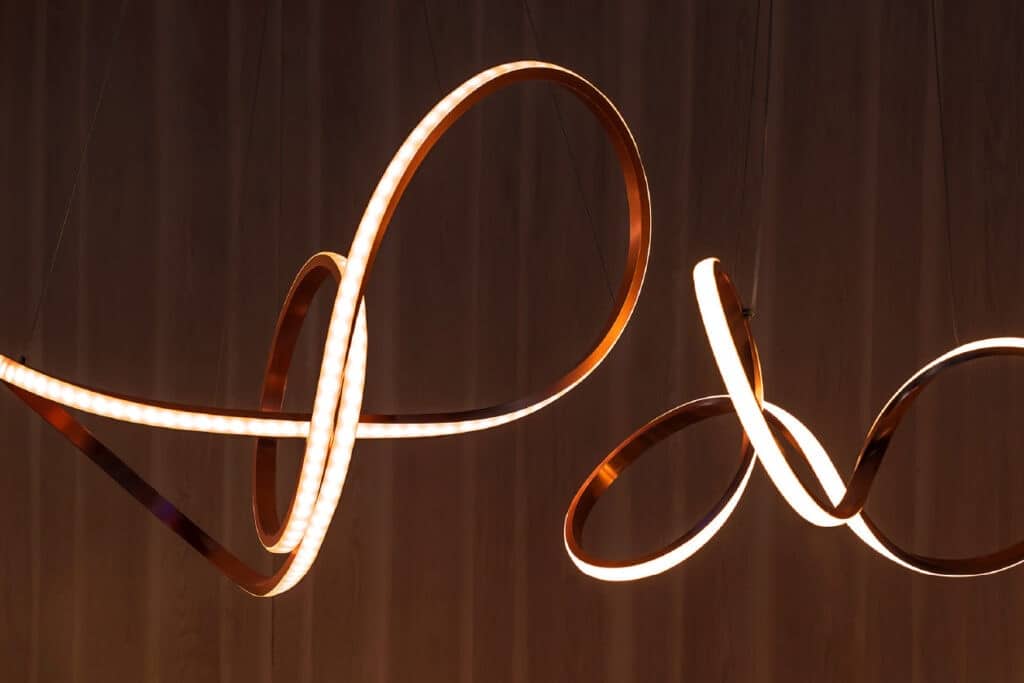

HPE stands for High Performance Elastomer and can adapt to many types of applications: wheels, bellows, gaskets, concrete moulds etc.