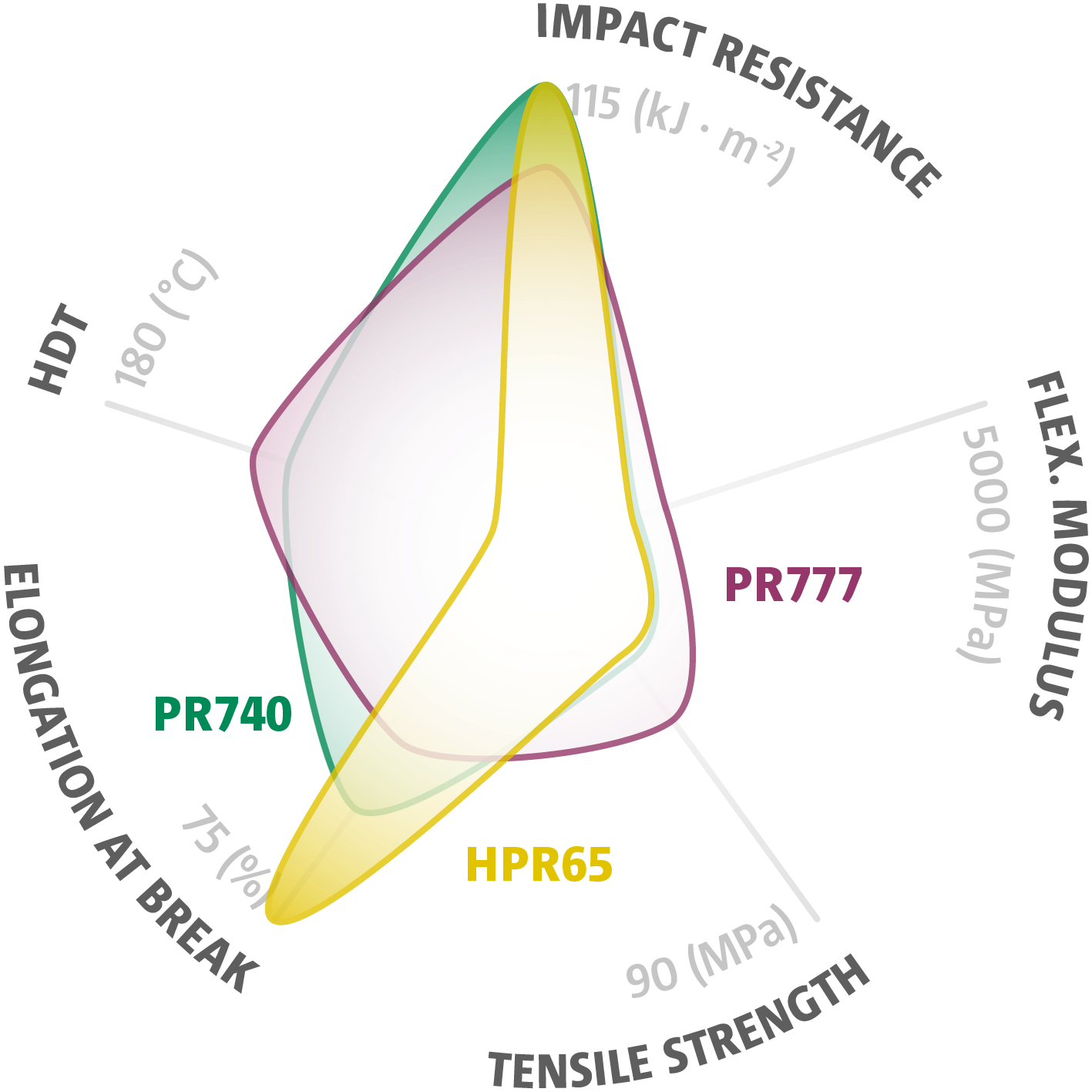

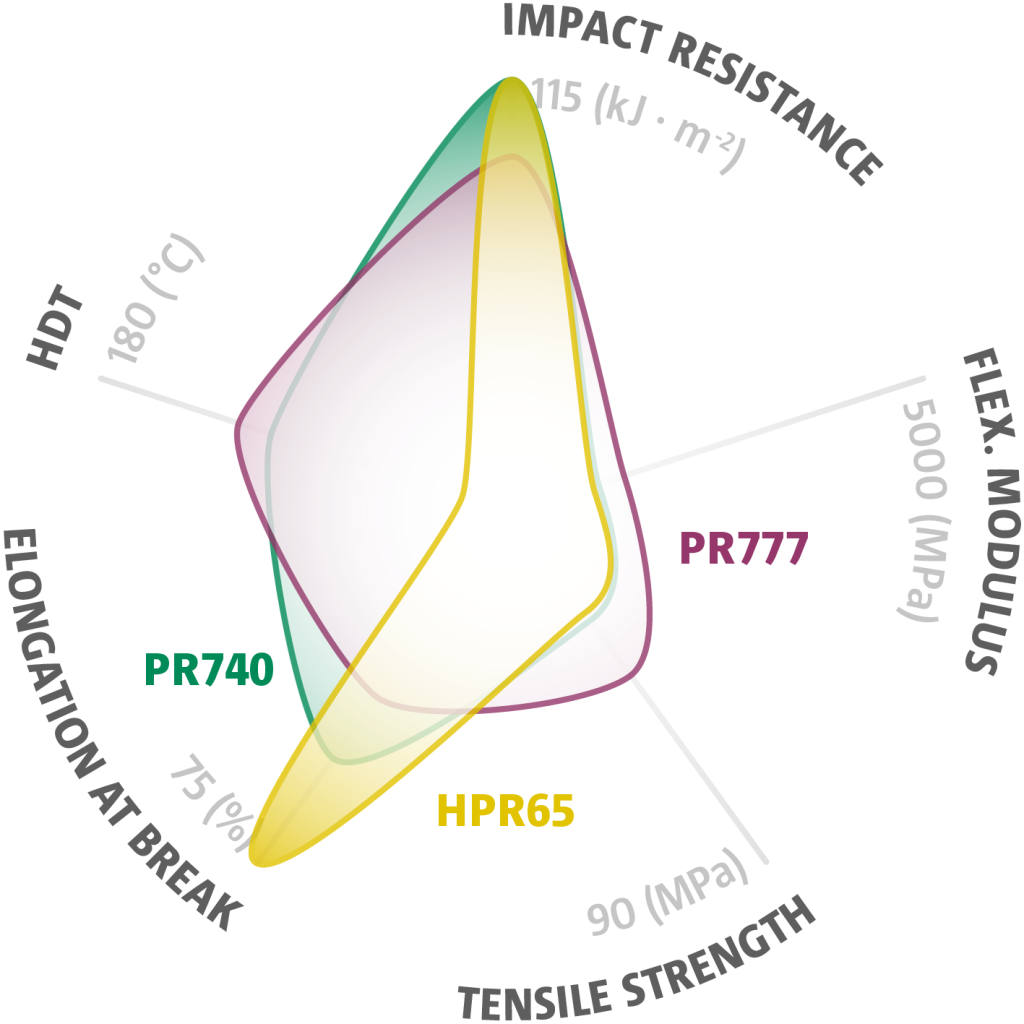

the Flexible PR740

- Suitable for living hinges and very resistant to torsional and bending forces

- Limited isocyanate aggressiveness to ensure long mould life

- High chemical resistance to various aqueous solutions and engine fluids

- Overall good mechanical resistance with very high elongation at break > 50% and high impact resistance even notched

Documents

TDS PR740

Technical data sheet of the PR740. All mechanical and thermal properties of the flexible prototyping resin PR740.

- chemical resistance

- dielectric properties