the UL94 Certified PRA794

- The most popular resin to meet demanding flame-retardancy requirements

- The PRA794 benefits from UL organisation accreditation as UL 94 V0 recognized material

- Yellow Card available: E523647

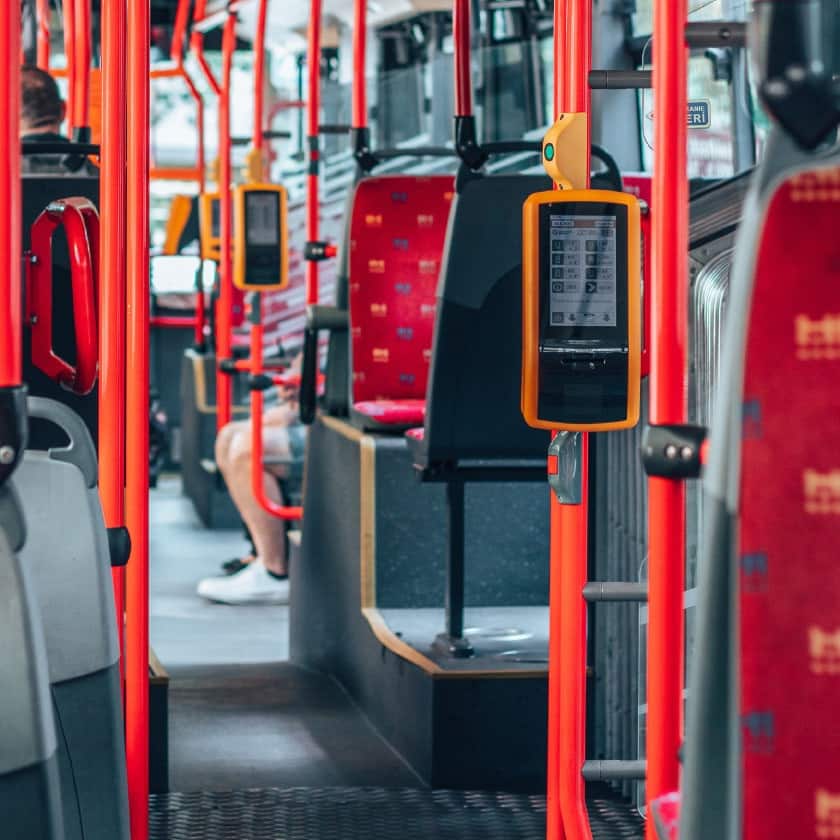

- Its self-extinguishing capabilities are necessary for most projects with an aero-spatial or electronic background and in public transportation

- Low aggressive isocyanate leads to extended life of the silicone moulds

Documents

TDS PRA794

Technical data sheet of the PRA794. All mechanical, thermal and fire resistance properties of the self-extinguishing prototyping resin PRA794.

+ download

(pdf | 0,3 MB)

available Test reports

- dielectric properties

- flame resistance

- thermal conductivity

- UL Yellow Card

Please contact us in order to get a copy of the test reports. We will happily provide them to you.